1factory : Lightning-Fast Quality Management Software

1factory: in summary

1factory is a cloud-based Quality Control and Quality Management System (QMS) designed for manufacturing organizations of all sizes—from small machine shops to global OEMs—across industries such as automotive, aerospace, medical devices, electronics and advanced ceramics. By digitizing document control, inspection planning, data collection and corrective actions, it empowers Quality, Engineering and Operations teams to:

Accelerate inspection and reporting workflows

Improve factory yield through real-time analytics

Streamline supplier and regulatory compliance

With built-in modules for inspection, PPAP/APQP, gage management and nonconformance handling, 1factory replaces paper-based processes and disparate spreadsheets with a unified, automated platform that scales with your operation.

What are the key features of 1factory?

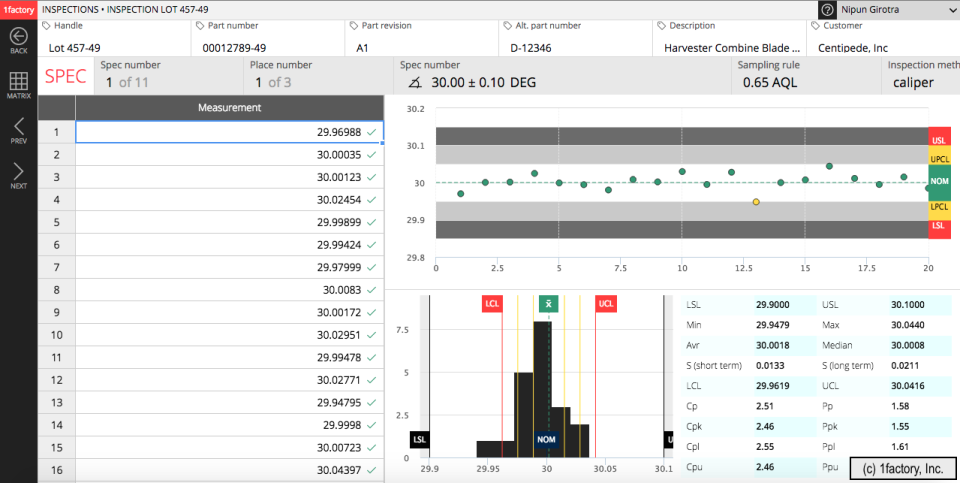

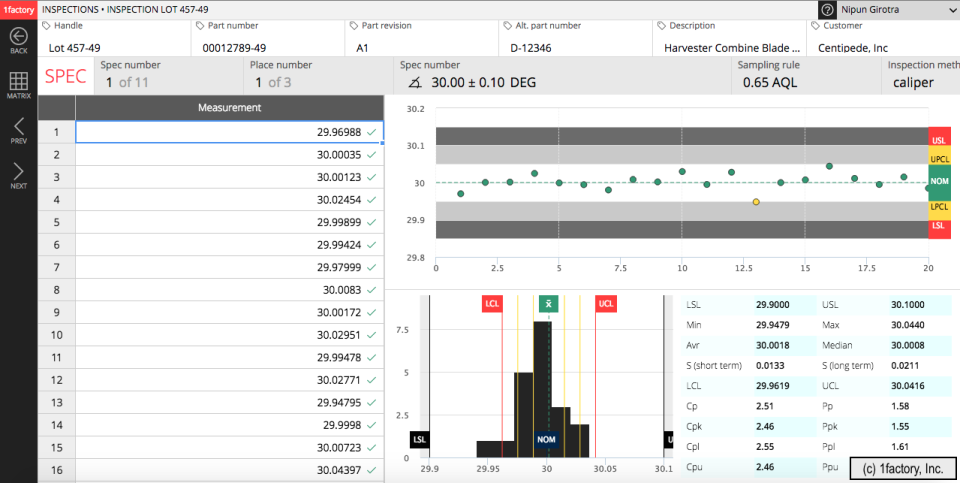

Robust manufacturing quality control

1factory’s core Manufacturing Quality module centralizes every step of in-process and final inspection. Users can:

Auto-balloon drawings to generate inspection plans in seconds

Collect measurement data via desktop, tablet or CMM integration

Monitor process stability with real-time Statistical Process Control charts

Trace inspection history through part genealogy and lot reporting

By combining drawing annotation, data capture and analytics in one interface, teams eliminate manual data entry, reduce transcription errors and gain immediate visibility into quality trends.

Simplified incoming quality management

The Incoming Quality module ensures critical components meet specifications before production:

Define sampling plans based on risk and supplier performance

Automate lot switching to allocate inspection effort where it matters most

Capture supplier certificates alongside inspection results for full traceability

Generate acceptance reports that align with international standards

This data-driven approach minimizes unnecessary inspections, lowers procurement costs and prevents defective parts from entering your production line.

Connected supplier quality management

1factory’s Supplier Quality module fosters seamless collaboration between OEMs and suppliers:

Share PPAP and FAI packages with external partners through a secure portal

Exchange inspection data in real time to surface issues before shipment

Track supplier performance with dashboards that highlight defect trends

Manage supplier corrective actions directly within the platform

By eliminating email chains and manual file transfers, organizations accelerate approval cycles, strengthen supplier relationships and reduce the total cost of poor quality.

Streamlined PPAP and APQP management

The PPAP & APQP module guides teams through new product introduction and change management:

Build PFMEA and Control Plans using preconfigured templates

Run Gage R&R studies and process capability analyses without external tools

Coordinate cross-functional reviews with automated approval workflows

Archive revision history for every document, test and study

These capabilities shrink PPAP cycle times from days to hours, enabling faster time-to-market and greater agility in responding to design changes.

Comprehensive gage calibration control

With the Gage Calibration module, you can maintain thousands of gages with full accountability:

Schedule calibrations automatically based on usage or calibration intervals

Manage tool transactions between tool crib, production floor and external labs

Assemble gage kits linked to specific inspection plans or work orders

Trace gage usage back to each measurement and part lot

This ensures measurement accuracy, prevents unplanned downtime and provides audit-ready records at your fingertips.

Integrated quality management system

Beyond inspection, 1factory’s QMS module unifies document and training management with issue resolution:

Author and control documents with versioning and approval routing

Assign and track training to ensure team competency and compliance

Log NCRs, CAPAs, SCARs and audit findings in a single issue-management hub

Maintain full audit trails for regulatory standards such as ISO 9001 and 21 CFR Part 11

By embedding quality planning and corrective actions into daily workflows, organizations stay ahead of regulatory requirements and foster a culture of continuous improvement.

To summarize

Faster workflows: Automates inspection, approval and data-analysis tasks to free up thousands of man-hours each year.

Higher yield: Delivers real-time SPC and traceability that drive process improvements and reduce scrap.

Reduced risk: Centralizes supplier and compliance data to prevent defects, audit findings and costly recalls.

Greater visibility: Provides role-based dashboards and reports that align quality teams, suppliers and leadership.

Scalable architecture: Supports global operations with cloud-based performance, 99.99% uptime and multi-site deployments.

1factory - 1factory-screenshot-0

1factory - 1factory-screenshot-0

1factory: its rates

standard

Rate

On demand

Clients alternatives to 1factory

Statistical Process Control software for quality control. Track trends, identify issues, and improve processes.

See more details See less details

GainSeeker Suite is designed to help businesses improve their quality control processes. With its statistical process control features, users can track trends, identify issues, and make data-driven decisions to improve their operations. The software is easy to use and provides valuable insights into key performance metrics.

Read our analysis about GainSeeker Suite

SPC software for monitoring quality control processes. Identify trends, track KPIs, and generate reports for compliance purposes.

See more details See less details

GSQA helps businesses optimize their quality control processes. Its advanced analytics enable users to identify trends and prevent quality issues before they arise. The software also tracks KPIs and generates reports to ensure compliance with industry standards.

Read our analysis about GSQA

SPC software for process control and improvement. Real-time data analysis, automated alerts, and customizable reports.

See more details See less details

ProFicient provides a comprehensive solution for monitoring and optimizing manufacturing processes. Its advanced analytics capabilities allow for real-time data analysis, enabling quick detection and correction of issues. Automated alerts and customizable reports streamline decision-making and communication, improving overall efficiency and quality control.

Read our analysis about ProFicient Appvizer Community Reviews (0) The reviews left on Appvizer are verified by our team to ensure the authenticity of their submitters.

Write a review No reviews, be the first to submit yours.