CR Auto Scheduler® –Production : Algorithm Powered Auto Body Shop Scheduling Software

CR Auto Scheduler® –Production: in summary

CR Auto Scheduler® – Production is an algorithm-driven scheduling software designed specifically for auto body repair facilities. It supports shop managers, estimators, and production teams in medium to large collision repair businesses by optimizing the repair process from intake to delivery. This production planning tool helps reduce cycle time, balance workload, and better allocate resources across bays and repair stations. By factoring in real-time capacity, staffing, equipment availability, and job complexity, it enables more predictable, efficient operations.

Unlike manual methods or generic scheduling tools, CR Auto Scheduler® – Production is built around the specific dynamics of collision repair. Its integration of capacity-based planning and automated load leveling between workstations or locations gives repair shops improved control over daily operations and overall throughput.

What are the key features of CR Auto Scheduler® – Production?

Automated repair scheduling using real-time shop capacity

At the core of the software is a dynamic scheduling engine that considers real-time variables from your shop:

Takes into account available technicians, equipment, and production bays

Automatically assigns jobs based on resource availability and job complexity

Adjusts schedules as staffing or conditions change throughout the day

This reduces bottlenecks and enables more predictable vehicle delivery times.

Workload balancing across teams and locations

The system uses an algorithmic model to load-level tasks, allowing shops to:

Distribute repair jobs according to technician specialization and workload

Coordinate workflow across multiple locations, when applicable

Prioritize jobs based on estimated hours or severity

This helps avoid overloading one team while others remain idle, maintaining steady productivity.

Cycle time reduction and efficiency tracking

CR Auto Scheduler® – Production is structured to reduce average cycle times and highlight areas of delay:

Tracks job progress through all repair stages

Highlights underperforming steps and areas for improvement

Encourages leaner operations with fewer hold-ups and rework

Over time, this translates to improved shop throughput and lower per-repair costs.

Estimator-driven scheduling support

The software helps estimators quickly slot in jobs during the intake process:

Suggests optimal repair start times based on current shop status

Gives estimators visibility into available capacity before committing to dates

Minimizes risk of overpromising to customers

This feature supports better customer communication and higher conversion of estimates to repair orders.

Data-driven forecasting and reporting tools

Shops can leverage built-in analytics to:

Review historical cycle time trends by repair type

Forecast future capacity needs based on current job inflow

Identify underused resources and adjust staffing accordingly

Decision-makers can plan confidently with a clearer view of operations.

To summarize

CR Auto Scheduler® – Production stands out as a specialized scheduling system tailored to the demands of auto body repair facilities. It delivers measurable advantages such as:

Shorter vehicle cycle times with more efficient job progression

Better use of staff and equipment through load-balanced scheduling

Higher estimate-to-repair conversion rates through real-time capacity insight

Increased shop throughput without added stress on personnel

Informed operational planning via built-in performance analytics

Its consistent use across major North American body shops demonstrates a strong track record of helping facilities grow volume while maintaining or improving repair quality.

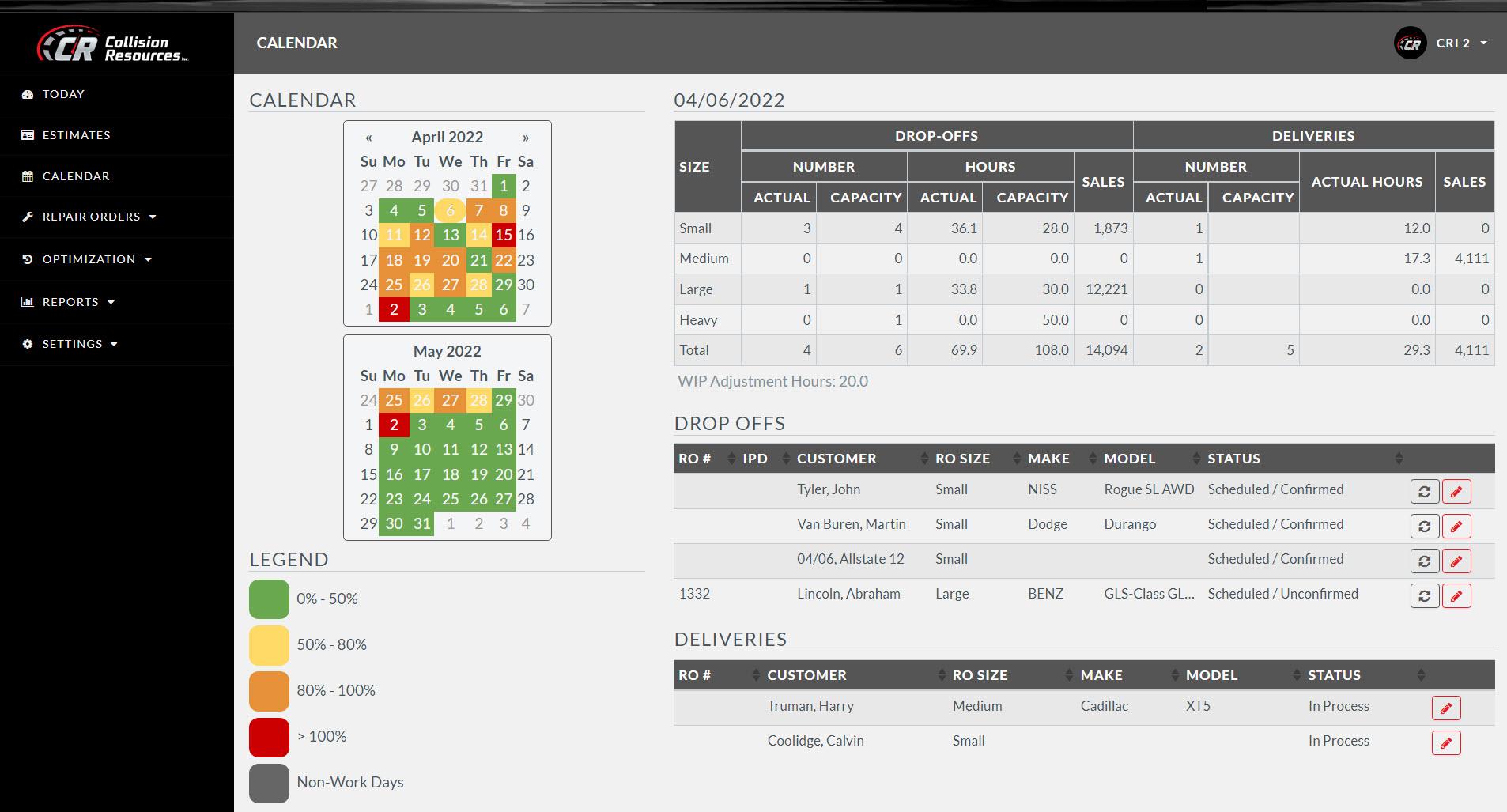

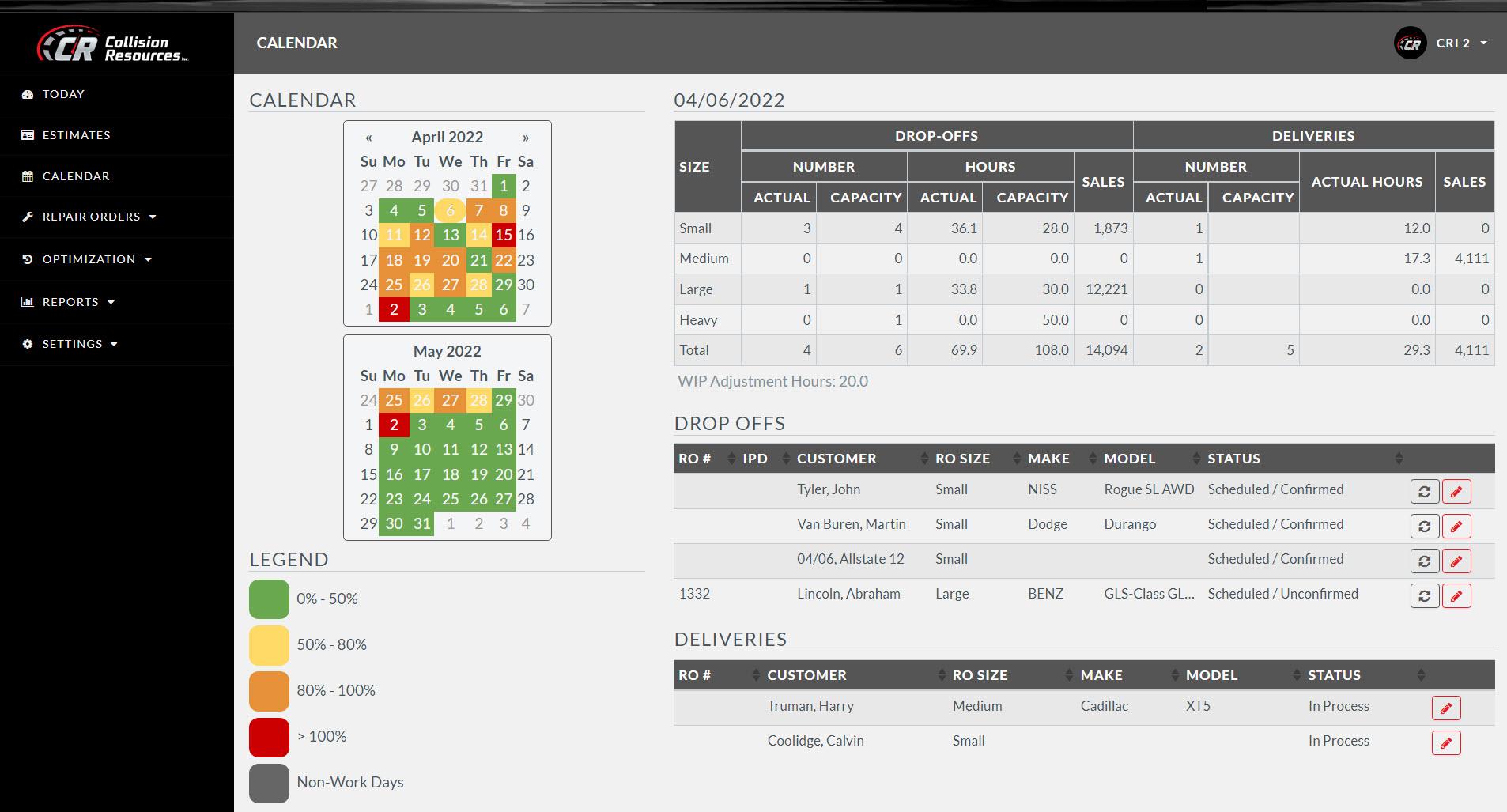

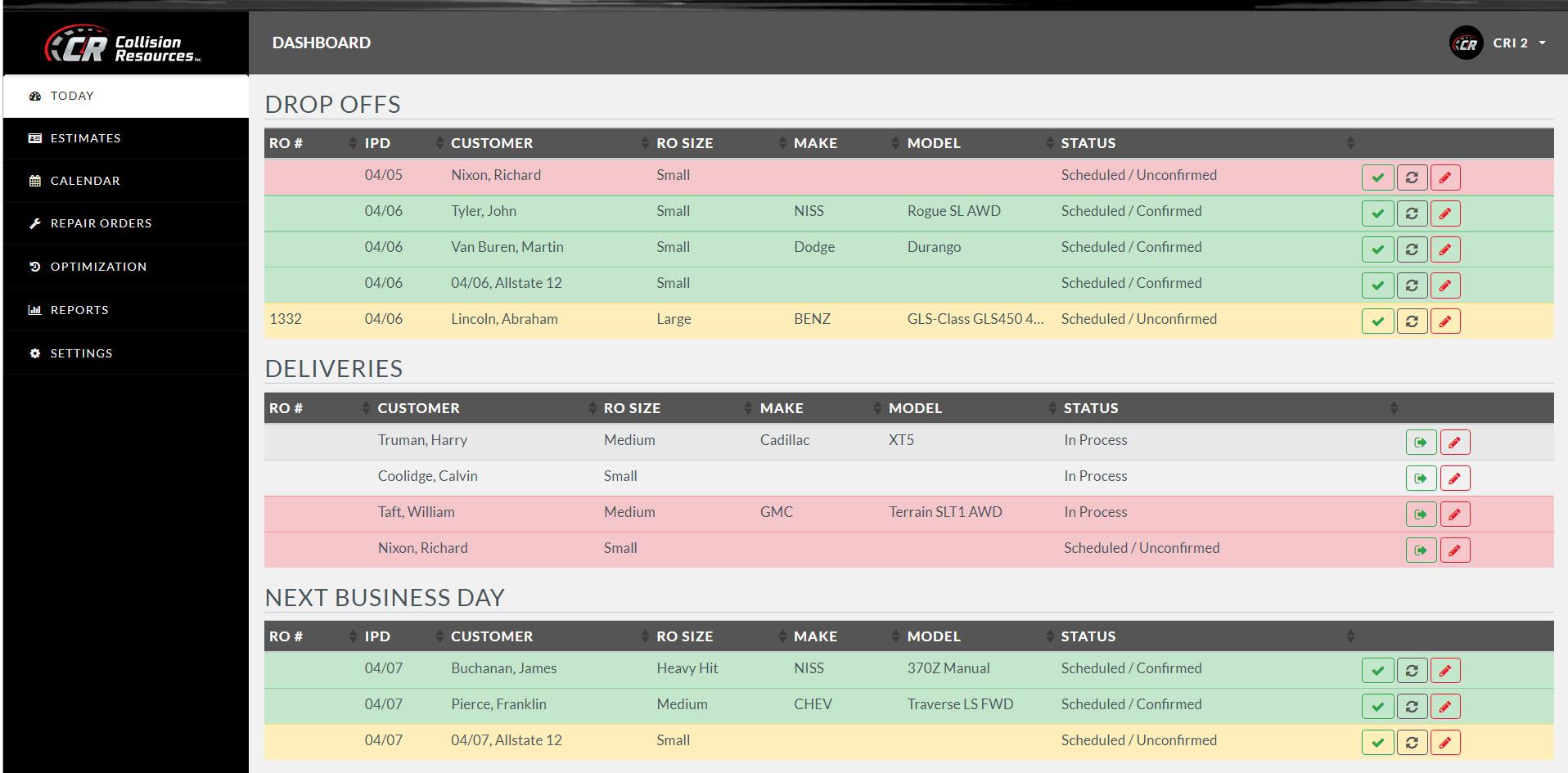

CR Auto Scheduler® –Production - Screenshot 1

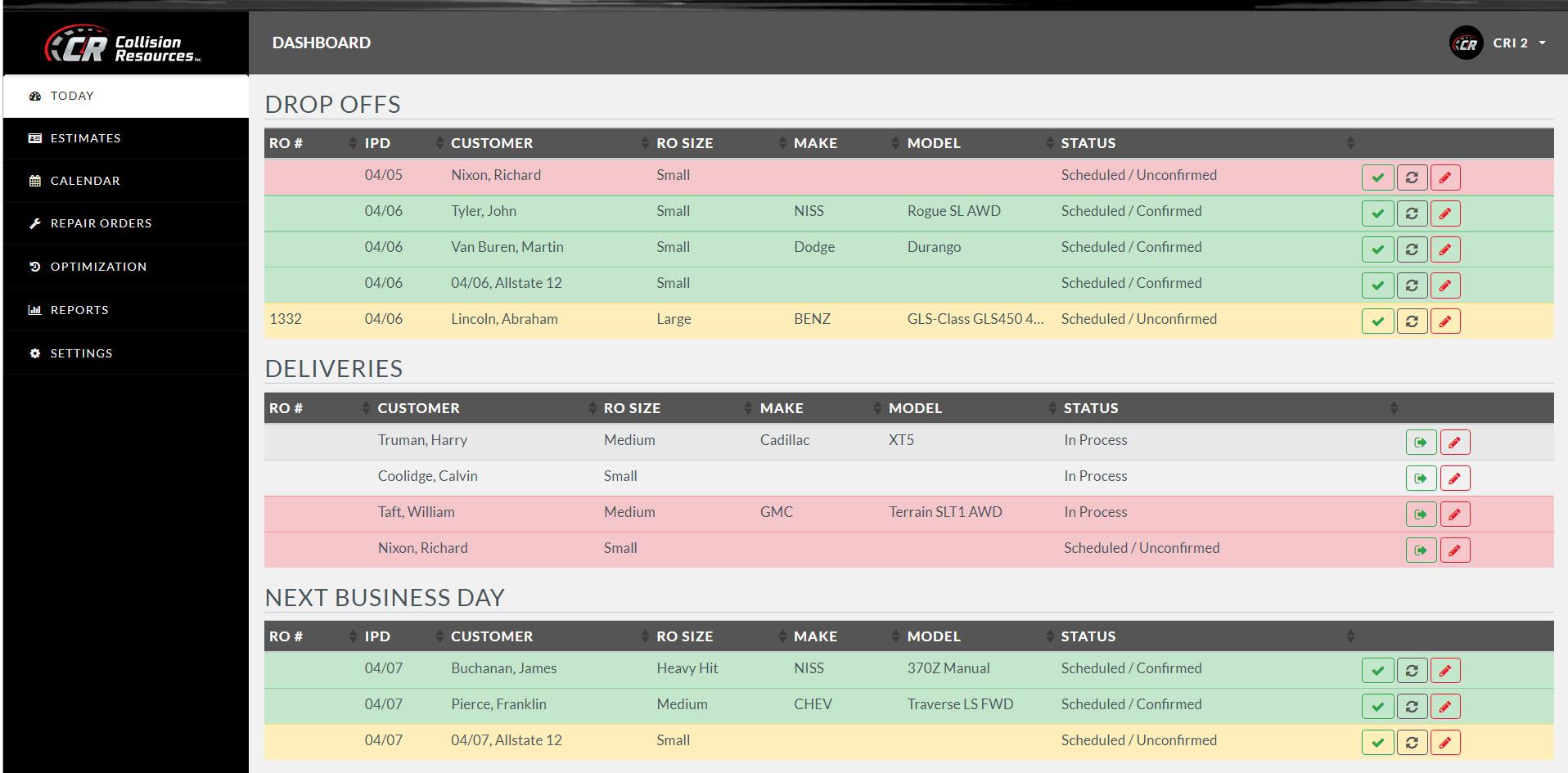

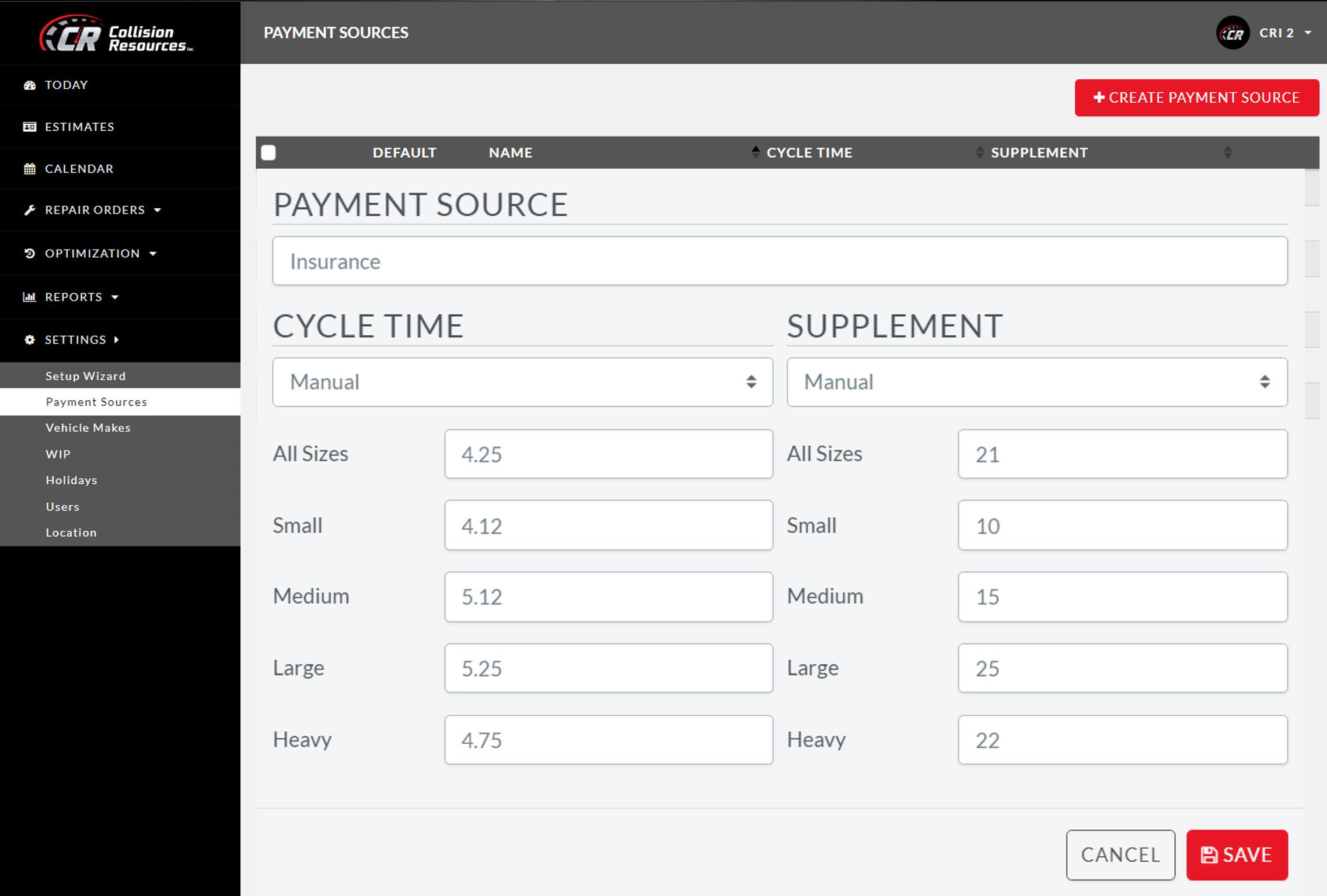

CR Auto Scheduler® –Production - Screenshot 1  CR Auto Scheduler® –Production - Screenshot 2

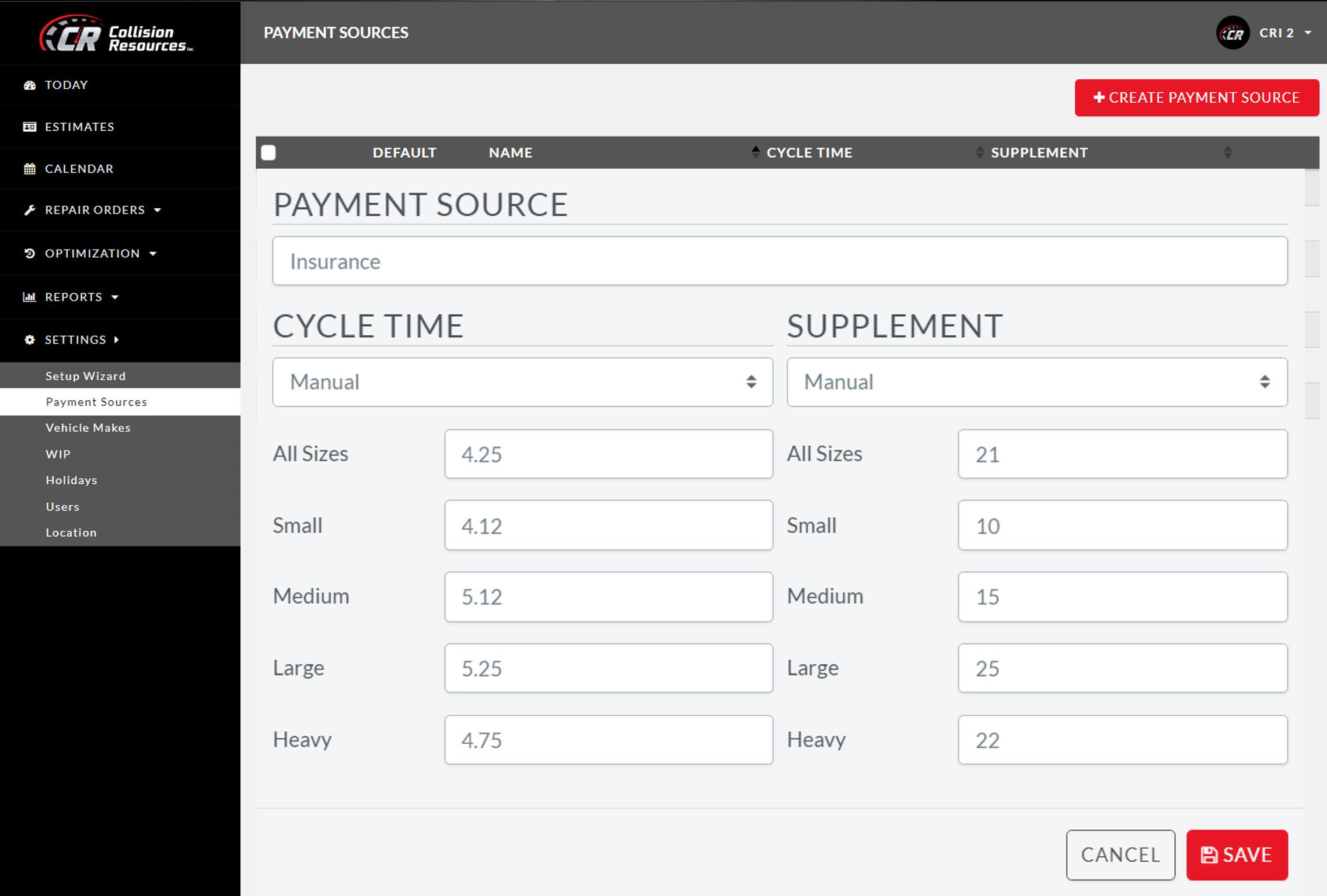

CR Auto Scheduler® –Production - Screenshot 2  CR Auto Scheduler® –Production - Screenshot 3

CR Auto Scheduler® –Production - Screenshot 3

CR Auto Scheduler® –Production: its rates

standard

Rate

On demand

Clients alternatives to CR Auto Scheduler® –Production

Streamline your auto body repair process with our software. Manage appointments, inventory, estimates, and invoices all in one place.

See more details See less details

Our auto body repair software simplifies your workflow so you can focus on your customers. Keep track of job statuses, schedule appointments, and generate detailed reports to improve your business.

Read our analysis about Repair FacilityTo Repair Facility product page

Streamline your auto body shop with software designed to manage customers, estimates, and workflow.

See more details See less details

With this cloud-based solution, you can easily create and track work orders, manage inventory, and streamline billing. Get real-time updates on technician productivity and job progress, allowing you to make informed decisions and optimize your shop's performance.

Read our analysis about Shop Boss ProTo Shop Boss Pro product page

Streamline auto body repairs with advanced management tools, seamless scheduling, and insurance integration for efficient workflow and customer satisfaction.

See more details See less details

Repair Soft offers a comprehensive solution for auto body shops, featuring tools that enhance management efficiency. Key capabilities include intuitive scheduling, effective parts inventory tracking, and effortless integration with insurance companies. This software is designed to simplify the repair process, ensuring faster turnaround times and improved customer communication. With robust reporting features, it also enables shop owners to analyze performance metrics and streamline operations for greater profitability.

Read our analysis about Repair SoftTo Repair Soft product page

Appvizer Community Reviews (0) The reviews left on Appvizer are verified by our team to ensure the authenticity of their submitters.

Write a review No reviews, be the first to submit yours.